Field operations are complex and continuously changing. Multiple adaptive advanced analytics models triangulate and automatically take mitigating action on inventory efficiency opportunities and risks.

Operations in the Medical Device industry are especially complex due to the expectation of zero failures. When sales teams fail to ensure the right assets are at the right place on time, the surgery does not happen using their product, and worse—patient care is compromised. Additionally, the cost of these assets is extraordinarily high relative to products in other industries. Failure to manage field inventory effectively results in poor asset utilization and increased excess and obsolescence expenses. Meanwhile, growing organizations must have the right asset management practices in place to achieve the efficiency and growth objectives necessary for scaling.

Proven Strategies

A demonstrated effective approach addresses field asset management in three key parts:

Consignment Modeling, Demand Modeling, and Forecasting Demand The combination of these three practices leads to powerful, data-driven decisions that enable med device enterprises to get the most efficiency out of their assets. The result is increased asset utilization, less labor spent chasing products, decreased freight spend, decreased E&O expense, and a happier, more productive sales force.

1: Consignment Modeling

Modeling consignment enables sales and operations teams to evaluate which assets to park at hospitals, ASCs, and physician offices. Effectively implementing Consignment Modeling ensures resources are always closest to where they are sold—the operating room.

Consignment Modeling measures consumption by facility and allocates assets according to facility sales. Inventory teams historically struggle with foundational consignment analysis when taking the model from the conference room to the field. The analysis often falls apart when presented to field team members because the models do not make clinical sense. Consumption Modeling alone does not capture the clinically required carrying costs built into each surgical technique. This is the fatal flaw in traditional ERP-driven models.

The solution is to combine traditional consumption modeling with surgical grouping features such as Kits, Non-Stockable Kits, and Bundles. If the surgical grouping of product exceeds the turn goals, a single set of product is parked. Statistics are leveraged to add additional units of each SKU. As a result, the model bridges the clinical need perspective (field sales users) and the financial strategy perspective (corporate asset management teams).

2: Demand Modeling for Loaner Locations

The second key component to an effective asset management strategy is modeling demand. Demand is the signal for loaned assets required for surgery and is completely distinct from consumption. Rather, demand is the requests and movement of assets to cover surgical needs. This is a data point that most ERPs fail to capture. It represents the bulk of inventory movements within many med device companies’ business models.

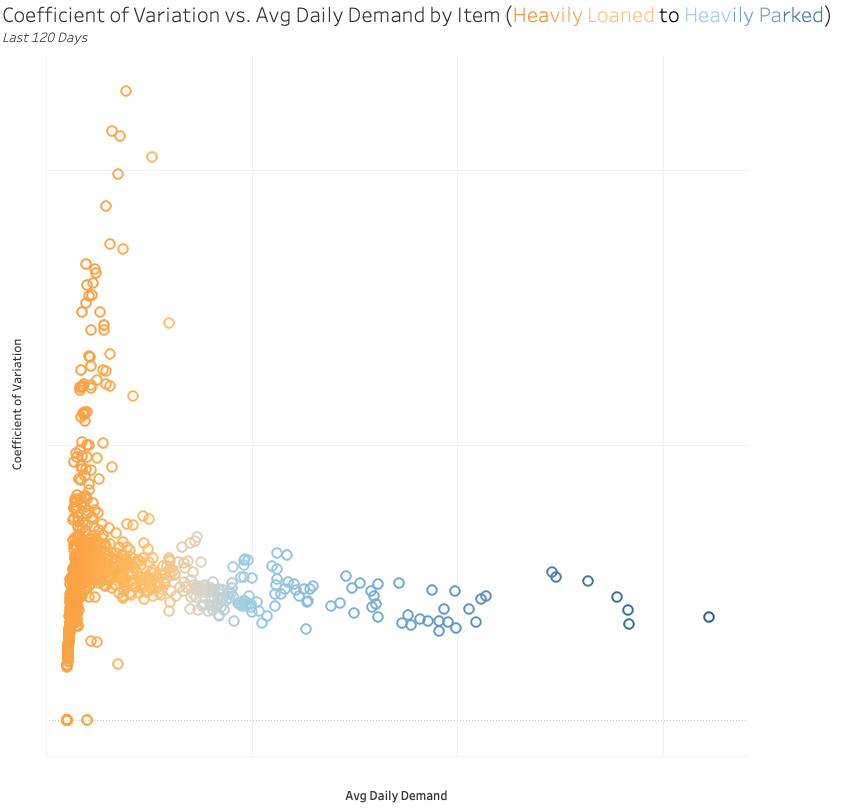

Consign versus loan decisions should be based on two key factors: Demand, and volatility of Demand. As demand decreases and volatility increases, organizations experience decreased efficiency in their consigned assets. Parking these assets results in increased E&O spend and more expired product in customer accounts. To combat this issue, many med device organizations operate loaner pool operations to satisfy outlier demand.

However, the more effective approach is to track the demand and the cycle time of assets when they are loaned. With this data, it is possible to successfully model the loaner environments to enable them to achieve their target service levels. Applying statistics enables an accurate allocation of resources to these under-analyzed environments. Historically, the outcome of this analysis drives 15-25% asset reductions, and increased labor efficiency by rebalancing the assets to the locations they are most needed.

3: Forecasting Growth

Forecasting is the third component to this Asset Management strategy. Expert analysts can forecast at a variety of levels by leveraging detailed case volume data and machine learning techniques. Using data from a comprehensive sales and inventory platform with analyzed proven forecasting methods is able to predict case volumes into the future. And as with any forecast, the more data analyzed, the more accurate these forecasts become–regardless of preferred method: Top-Down, Bottom-Up, or Grouped.

By leveraging forecast models at the procedure and sub-procedure level, our clients can feed their MRP systems to increase or decrease their forecasted sales at the SKU and set level. These forecasts are usually within 10% variance with just 1 year’s case data.

Finally – Data-Driven Results

Movemedical models consignments to drive the right product closest to the point of sale, and it models demand to ensure assets required are always available to the field sales organization. These models consistently deliver increased asset turns, reduce freight spend, and drive a streamlined field sales operation. Finally, Movemedical builds forecast models to provide manufacturing teams the right information to produce the products most likely to be required in the coming.

Each of these models is built using passively collected data from clients using the Movemedical platform. As a result, no behavioral changes are required from field users and the models continually update as business trends change. This key factor allows better, data-driven decision making, which enables higher success in reaching asset management objectives.

Field operations in the medical device space is a complex environment. Movemedical encourages manufacturers to leverage multiple types of analytics to drive high asset utilization and make data-driven decisions that help them achieve their financial and asset management goals by using these advanced data models.

Optimize Your Inventory – Connect With Us

If an in-depth forecasting and field inventory management discussion makes sense – contact us here: info@movemedical.com / call 877.469.3992 or watch this VIDEO (executive case study)

Related Articles:

Learn More About Advanced Analytics for Inventory Management and Operational Excellence: