By leveraging consignment loan performance metrics, par levels can be maintained through automated orders.

Going a step beyond calculating optimal consignment inventory levels (previously addressed in the article Advanced Analytical Models for True Medical Device Inventory Consignment Optimization), the present article demonstrates how consignment loans can be leveraged to set par values through automated new stock and return orders—driven by the par values set in the consignment loan. Also addressed is how to effectively measure the performance of consignment loans and compliance to par levels.

Creating Consignment Loans

Most mature OEMs already have established analytics models that set consignment par levels. But the real value comes when these models are operationalized. A demonstrated best practice is to review the consignment model output with local sales teams to determine the final par levels before operationalizing them. This important review step allows the local sales teams to make final adjustments to the inventory level based on their sales strategies and local knowledge.

A comprehensive automated inventory platform will enable users to bulk upload consignment par levels into consignment loans. Consignment loans formally define inventory levels for individual SKUs by location for a specific service period. These loans are each tied to a facility, business unit, and service date range for the inventory.

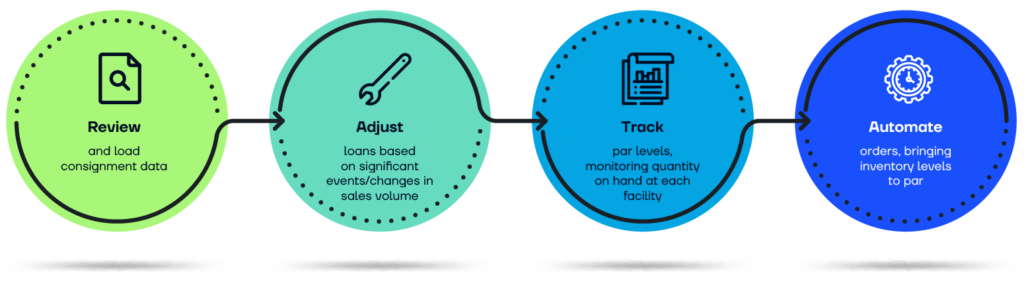

A best practice is to review and load consignment data annually, adjusting the loans based on significant events or changes in sales volume. The consignment loan keeps track of the par levels and continuously monitors the quantity on hand at each facility. Any item related to the same business unit should be included in the quantity on hand, regardless of whether it was included in the consignment loan. This helps account for all products, rather than only the specific SKUs intended to be consigned at that facility. And this process helps identify all inventory at par, below par, and above par.

Consignment Loan Order Automation

Realizing the true value of effective consignment loan management requires automatically generated orders. Gaining buy-in of local teams during the implementation phase of consignment loans is facilitated by focusing on one of two aspects at a time:

First: Focus on the shortages at each facility.

Concentrating on inventory deficits ensures that sales teams have all the products they need to support their cases successfully. It also helps with the change management associated with consignment loan implementation.

Once consignment loans are live, changes between the quantity on hand and the par level should be monitored in real time, and any shortages returned to par with automated restock orders.

Second: Focus on the inventory overages.

Automatic generation of consignment return orders on these loans reduces excess inventory. Inventory can be returned to a local supporting office, returned to a regional distribution center, or redeployed to other consignment locations to fill inventory shortages. Addressing the overages in consignment loans can lead to enormous savings in inventory while reducing future inventory build plans—as significant inventory is redeployed instead of manufactured.

Measuring Consignment Loan Health

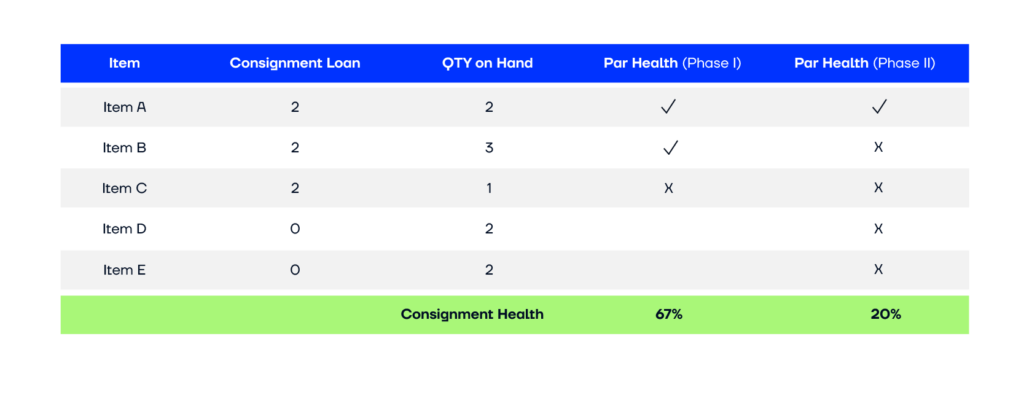

The final component to operationalizing consignment loans is tracking of consignment loan health using two KPIs, rolled out in phases. This enables effective change management.

First KPI: the percentage of items at each facility at or above par, over the total SKUs.

Ideally, facilities should be close to 100% consignment health, implying all inventory at the facility is at the par level or above. Once the shortages have been met and consignment loan health is in the upper 90s, field sales reps have confidence that they have the assets required to support their sales.

Once the first KPI is healthy, we move to the second KPI, which introduces the overages.

Second KPI: categorize SKUs as healthy only when exactly at par

Count inventory levels that are at par, not over, and not short. This KPI will help drive the returns of overages because they are now considered unhealthy. In addition, inventory that does not have a consignment level but is part of the same business unit will be included and considered unhealthy.

Example 1: Consignment Health Calculation

Example 1 above illustrates how the two different KPI calculations work, and Example 2 below is a dashboard view, demonstrating how this data can be visualized for a region.

Example 2: Consignment Health Dashboard

The recommended best practice is to track consignment health in two phases, ensuring all agreed-upon inventory is available to support cases before tackling inventory overages. This seamless experience gives OEMs the power to understand and manage their field assets much more effectively than otherwise possible.

The native functionality available in the Movemedical platform enables our clients to set, automate, and manage their consignment locations. The ability to bulk load pars, automate the orders to right-size consignments, and track performance are all keys to our clients’ inventory optimization success.

If a discussion on operationalizing your consignment par levels makes sense, let’s talk:

Contact us here: info@movemedical.com / call 877.469.3992 or watch this VIDEO (executive case study)